How to extend the life of used car parts?

Investing in functional, used parts is a smart way to save on car repairs without sacrificing the high quality of original OEM parts. However, for used car parts to last as long as their brand-new counterparts, they require proper care from the moment of purchase. The key to success lies not only in choosing a reliable source, like Global Parts, but above all, in properly maintaining the used parts before installation. Processes such as car part cleaning and professional anti-corrosion protection of bodywork parts help avoid many future problems. Systematic inspection of used parts and adherence to installation guidelines can extend their lifespan by thousands of kilometers. Knowing how to extend the life of used car parts is fundamental to your vehicle's reliability.

Rules for extending the life of used car parts

Properly preparing parts before installation is half the battle in ensuring their long-term reliability and smooth operation in the system. Thorough inspection of the used part's condition, followed by thorough cleaning and maintenance before installation, is essential. Many people make the mistake of installing components straight out of the box, which in the case of mechanical components can drastically shorten their service life. A professional automotive shop, Global Parts, supplies proven used parts, but processes such as seal replacement are the responsibility of the installer. Checking for leaks, the condition of moving parts, and removing old deposits eliminates the risk of failure immediately after leaving the workshop. Attention to detail during the preparation phase ensures the true durability of mechanical components.

Car parts cleaning and surface preparation

Removing old deposits, carbon deposits, and grease allows for a precise technical assessment of the purchased component and facilitates its subsequent maintenance. The cleaning process should be closely matched to the component's material to avoid damaging its delicate structure. For aluminum parts, ultrasonic cleaners or dedicated chemicals are recommended, while steel parts may require pressure degreasing. A clean surface allows for the application of fresh lubricants, which is crucial for components such as the differential, steering knuckle, and other moving chassis parts. Aggressive sandblasting at seal contact points should be avoided, as this can lead to subsequent fluid leaks. A properly prepared part dissipates heat better and is significantly more resistant to the buildup of new road debris.

Storing car parts before assembly

Ensuring proper storage conditions for purchased components is crucial if you don't plan to install them immediately in a vehicle. Components should be stored in a dry and well-ventilated area, which effectively prevents metal oxidation and rubber evaporation. Components such as differentials and engines should be protected with a layer of preservative oil and wrapped in vapor-permeable foil to prevent moisture. Recycled electronic parts require protection from electrostatic discharge and extreme temperature fluctuations. Improper storage can cause even the best-quality components to fail before they're even started in a new car. Careful storage is an investment in the quality of the dismantled parts.

Maintenance and service life of spare parts in the drive system

Servicing recycled drivetrain parts begins with the complete replacement of all fluids and seals with brand new ones. The engine and differential are the heart of the vehicle, requiring the utmost precision in maintenance after purchasing aftermarket components. It's common for differentials to have been stored for some time, which promotes natural moisture condensation inside the housing. Therefore, before the first start-up, the oil in components such as differentials should be changed, maintaining viscosity parameters strictly in line with the manufacturer's specifications. Checking the flange clearances and bearing condition allows you to identify any irregularities before costly and labor-intensive installation. Such precision ensures that the purchased parts will operate quietly and flawlessly.

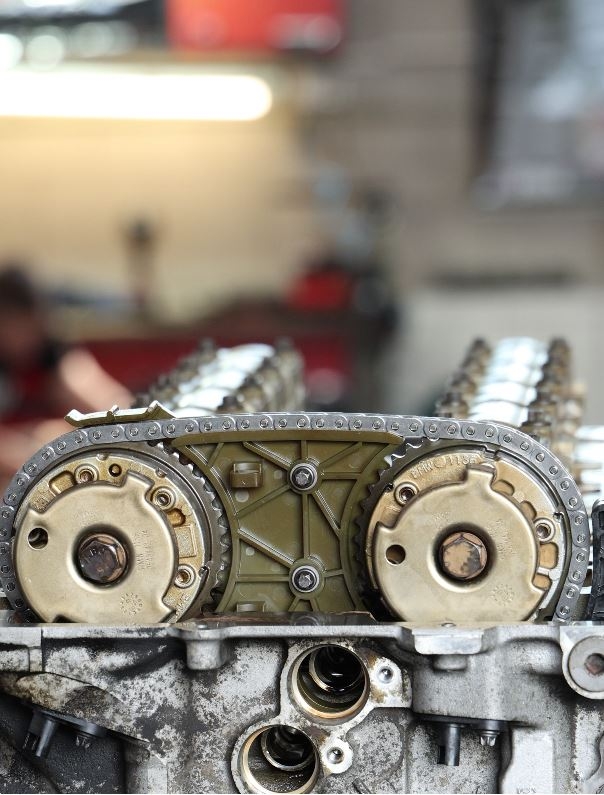

How to extend engine life after replacing the post?

The new life of a disassembled engine, such as the popular N47 diesel or M54B30 petrol, depends largely on the quality of the fluids and the initial start-up. Before installing a used engine, it's worth performing a starter kit, which includes replacing the timing belt, water pump, and valve cover gasket . In engines like the BMW N47, checking the condition of the timing chain is crucial, while in the M54B30, attention should be paid to the proper functioning of the air intake system. Using high-quality synthetic oils with the appropriate viscosity (e.g., 5W30) drastically reduces internal friction and flushes out old deposits. Cleaning the intake system of carbon deposits is also recommended, which optimizes the combustion process and directly protects the pistons. Proper adaptation of the controller after installation is the final step towards many years of trouble-free operation.

Maintenance of differentials and differential gears

Stable drivetrain operation requires impeccable tightness and a lack of metal filings in the gear lubrication system. The differential is the component most likely to fail due to leaks through the axle shaft seals or drive flange, which leads to overheating. Before assembly, it's worth replacing these small rubber components, which cost a fraction of the component's cost, to avoid having to disassemble them again quickly. Checking the tooth gap and the condition of the housing for cracks is absolutely essential when inspecting a used part in a professional workshop. It's also important to clean the differential breather, which prevents excessive buildup of gas pressure inside the housing during operation. Maintaining the quality of the gear oil (e.g., GL-5 grade) ensures smooth torque transfer.

Taking care of used suspension and bodywork components

Aesthetics and safety go hand in hand with proper mechanical preparation of the chassis and effective anti-corrosion protection of the bodywork. Components such as the steering knuckle and reclaimed control arms are constantly exposed to road salt, so their maintenance should include removing rust deposits. Reconditioning automotive suspension components often involves replacing the metal-rubber bushings with new ones, restoring their full rigidity. For bodywork parts such as hoods and fenders, it's crucial to inspect the internal hollow sections for corrosion. The use of technical waxes or bitumen sealants protects these components from the harmful effects of weathering. This type of maintenance ensures that the parts will last for seasons to come in harsh road conditions.

How to care for bodywork and visual details?

Used visual details, such as a BMW E46 steering wheel or gear shift knob, often show signs of wear and tear, which can be easily removed with professional cleaning products. Regular cleaning of leather car parts protects them from cracking, while plastic parts require maintenance with UV-protective products. When it comes to wheels, it's worth checking whether the wheel hub caps are securely attached to prevent accidental loss during high-speed driving. With proper maintenance, visual parts can look almost new, pleasing the owner's eye every day. Saving on car repairs with salvage parts doesn't have to mean compromising the aesthetics of your car's interior. Using genuine, recycled parts is an eco-friendly and economical choice for every driver.

Taking care of electronic components and the rules for their installation

Electronics are the most delicate area, where clean contacts and stable supply voltage determine the durability of the modules used. Every comfort module or other control unit after disassembly should be inspected for traces of tarnish or corrosion on the connection pins. Before installation, it is recommended to use a contact preparation, which improves conductivity at the connectors and protects against moisture. It's important to remember that installing modern electronic components often requires professional programming and matching to the VIN/OEM number . A stable charging system in the car, based on a functioning alternator, is the best protection for the electronics used, preventing dangerous overvoltages. Taking care of electronic components guarantees no annoying errors on the dashboard.

Methods of extending the service life depending on the type of part

| Part type | Preservation method | Frequency of activities |

|---|---|---|

| Engine (e.g. n47, m54) | Oil change every 10,000 km, seal inspection | Once a year / upon installation |

| Differential and mechanisms | Gear oil change, breather cleaning | Upon installation / every 60,000 km |

| Suspension (knuckle) | Rust removal, pin lubrication, new bushings | During assembly / seasonal inspection |

| Bodywork (fenders) | Anti-corrosion protection of profiles, waxing | Once a year before winter |

| Electronics (modules) | Cleaning the contacts with contact preparation, drying the sockets | During assembly / in case of failure |

Used Part Assembly Comparison: Direct vs. Prepared

| Parameter | Direct mount | Assembly with preparation |

|---|---|---|

| Risk of failure immediately after installation | High (hidden leaks, dirt) | Very low (verified condition) |

| Component lifespan | Average (depending on history) | Maximum (extended by service) |

| Aesthetics of the element | Low (dust, deposits) | High (cleaned, preserved) |

| Total cost | Seemingly lower | Higher by the cost of chemicals and seals |

| Guaranteed reliability | Uncertainty | The highest level of security |

FAQ – Frequently asked questions about the lifespan of used parts

| Question | Answer |

|---|---|

| How to extend engine life after replacement? | It is crucial to change the oil to a high-quality synthetic, clean the intake, and replace the gaskets and timing belt before the first start-up. |

| Is cleaning parts necessary? | Yes, removing dirt and deposits allows for an accurate technical assessment of parts and prevents premature wear of moving parts. |

| How to care for used electronics? | It should be protected from moisture and contact preparations should be used to ensure perfect current conduction. |

| Is it worth lubricating differentials? | The differential requires fresh gear oil and the breather valve should be checked for blockage to prevent overheating and leaks. |

| How to protect sheet metal from rust? | The most effective way is to clean the surface and use technical waxes for closed profiles and bituminous masses for the exterior. |

| Does the crossover require service? | A used steering knuckle should be cleaned of rust, and its pins and bushings should be checked for play before installation. |